PRODUCTS

Two-Platen Injection Molding Machine for Plastic Bucket

Catalog:

keyword:

Two-Platen Injection Molding Machine

Detail

-

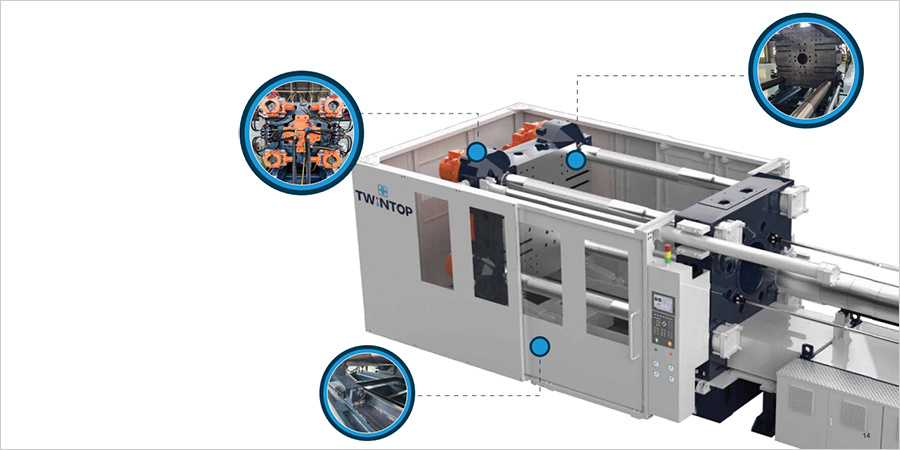

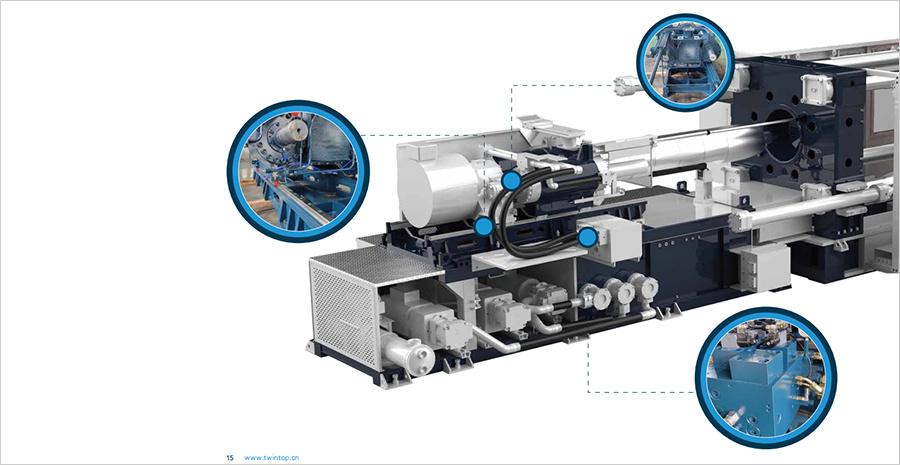

In interactive cylinder design, pressurized mold opening reduces the force of the mold opening cylinder and prolongs the life

-

Ample space between tie bar & long distance of opening stroke, which is especially good for products with big or deep size

-

Using high rigidity linear slides, the injection action has low resistance, stability and long-lasting durability

-

Easy to operate Clear function on the panel

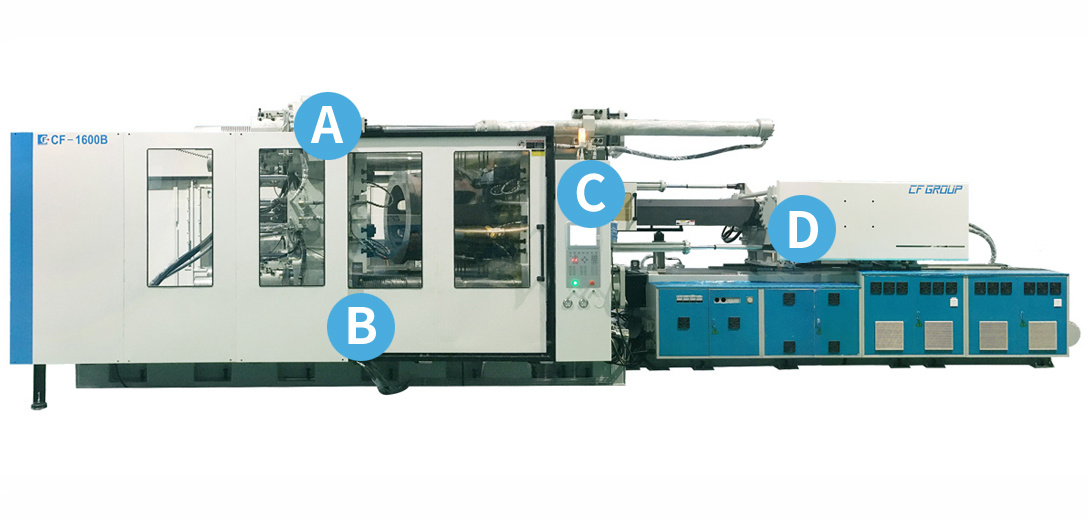

A:Interactive cylinder design, pressurized mold opening reduces the force of mold opening cylinder and prolongs life

B:Large space between tie bar & long distance of opening stroke, which is especially good for products with big or deep size

C:Easy to operate Clear function on panel

D:Using high rigidity linear slides, the injection action has low resistance, stability and long-lasting durability

FUNCTION LIST

| Injection Unit | ||

|

Function Description |

●Standard |

◎Option |

|

Standard screw |

● |

|

|

Double balance cylinder by injection structure |

● |

|

|

Display screw rotation speed |

● |

|

|

Plasticizing by hydraulic motor |

● |

|

|

Backpressure by proportional valve |

● |

|

|

Display injection pressure curve |

● |

|

|

Barrel supporting device |

● |

|

|

Feed zone temperature monitoring |

|

◎ |

|

Purger guard |

|

◎ |

|

Material-putting platform |

|

◎ |

|

Centralized lubrication |

|

◎ |

|

Ceramic heater |

|

◎ |

|

Infrared heating ring |

|

◎ |

|

Gas assisted injection interface |

|

◎ |

|

Hopper |

|

◎ |

|

Stainless steel hopper |

|

◎ |

|

Extended nozzle |

|

◎ |

|

Needle shut-off nozzle |

|

◎ |

|

Plasticizing by servo motor |

|

◎ |

|

Plasticizing by servo motor and gear box |

|

◎ |

|

Clamping Unit |

||

|

Function Description |

●Standard |

◎Option |

|

T-slot template |

● |

|

|

Intractive clamping device |

● |

|

|

Hydraulic & electric interlock device |

● |

|

|

Hydraulic safety protection |

● |

|

|

Automatic adjustment of mould height |

● |

|

|

Mold open & close and ejector transducer control |

● |

|

|

Automatic centralized lubrication of quantitative |

● |

|

|

Adjustable sliding feet |

● |

|

|

High rigidity rail board |

● |

|

|

Automatic safety door |

● |

|

|

One set maniflod |

● |

|

|

2 sets of core pulling on moving platen |

● |

|

|

Safety pedal device |

● |

|

|

Screw hole template |

|

◎ |

|

European standard template |

|

◎ |

|

Tie bar puller system |

|

◎ |

|

Perspective maniflod |

|

◎ |

|

Quick coupling maniflod |

|

◎ |

|

Air valve |

|

◎ |

|

Sequence vavle |

|

◎ |

|

Mold Opening and ejection synchronization |

|

◎ |

|

Mold Opening and charging synchronization |

|

◎ |

|

Highten frame |

|

◎ |

|

Increase mold opening stoke |

|

◎ |

|

Decrease mold closing stoke |

|

◎ |

|

Pick up platform device |

|

◎ |

|

Hydraulic Unit |

||

|

Function Description |

●Standard |

◎Option |

| Servo motor system |

● |

|

| Oil suction locked device |

● |

|

| Increase pump motor capacity |

◎ |

|

| Accumulator rapid injection |

◎ |

|

| Inject servo Valve |

◎ |

|

| Oil level alarm |

◎ |

|

| Cold water valve |

◎ |

|

| Electric Unit | ||

|

Function Description |

●Standard |

◎Option |

| DIHZHOU controller |

● |

|

| Real time working condition monitor |

● |

|

| Monitoring for production data | ● | |

| Automatic shows error |

● |

|

| Injection pressure transfer holding function |

● |

|

| I/O monitoring display | ● | |

| Three-color warning light |

● |

|

| Servo motor overload protection |

● |

|

| Emergency stop button or safety door | ● | |

| 380V/16A 5-core power socket 2 sets |

● |

|

| 220V/16A 3-core power socket 1 set |

● |

|

| Cold start protection | ● | |

| Heating solid relay control |

● |

|

| Real time mold clamping force monitor |

● |

|

| Computer network central control system | ● | |

| KEBA controller |

◎ |

|

| 380V/32A 5-core power socket |

◎ |

|

| 380V/16A 5-core power socket |

◎ |

|

| 220V/16A 3-core power socket |

◎ |

|

| Servo power system transformer |

◎ |

|

| Euromap 12 manipulator interface |

◎ |

|

| Euromap 67 manipulator interface |

◎ |

|

| Hot runner control and interface |

◎ |

|

| Protective light grid device |

◎ |

|

| Safety relay monitoring |

◎ |

|

| Others | ||

|

Function Description |

●Standard |

◎Option |

| Standard color |

● |

|

| Adjustable leveling pad |

● |

|

| Manual book、Clamping bar、Standard spare parts | ● | |

| Quick mould change system |

◎ |

|

| Anchor bolt |

◎ |

|

| Special color |

◎ |

|

| Robot |

◎ |

|

| Hopper magnet |

◎ |

|

| Chiller |

◎ |

|

| Mold temperature controller |

◎ |

|

| Dehumidifier |

◎ |

|

| Auto-loader |

◎ |

|

| Crusher |

◎ |

|

| Blender |

◎ |

|

| Dryer |

◎ |

|

Featured Products

Messages

If you are interested in our products, please leave us a message and we will contact you as soon as possible!