PRODUCTS

Toggle type Injection Molding Machine for Plastic Lids

keyword:

Hot Products

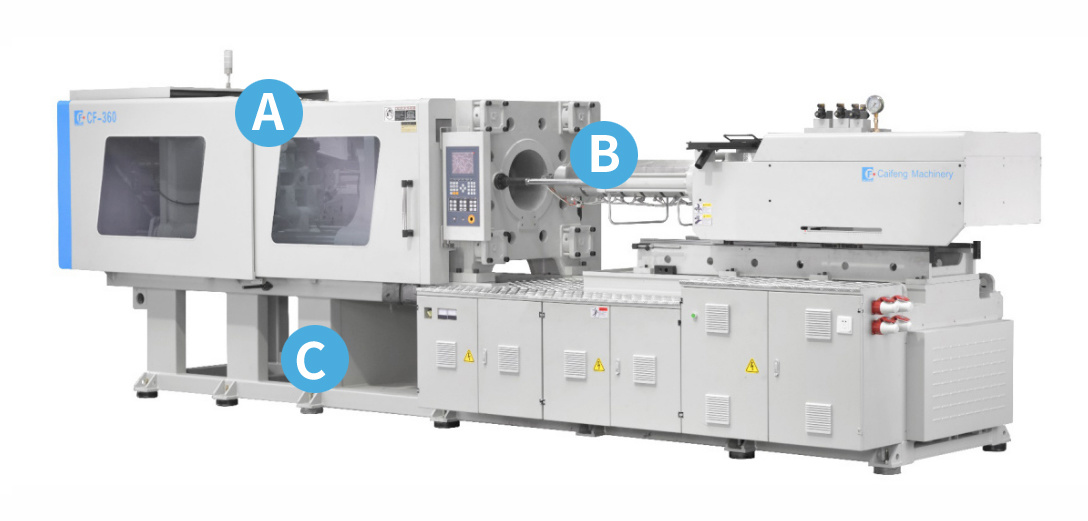

Toggle type Injection Molding Machine

Detail

-

Hot rolling type steel by heat treatment with excellent strength and hardness,Quench hardened with great strength.

-

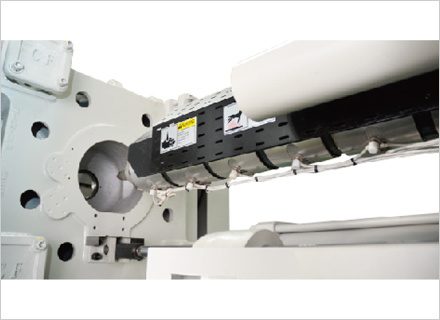

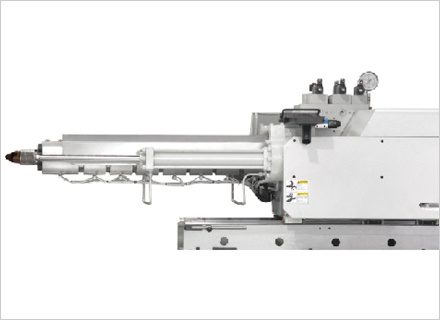

Configure professional screw according to customer's raw material, effectively increase plasticization and wear resistance

-

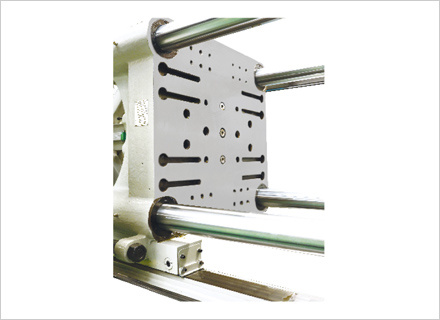

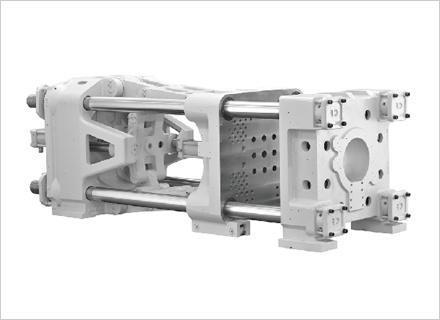

Use FEM to analyze the BOX structure machine wall, and use high-rigidity formwork to make the molded stress evenly increase the machine wall life

A:Use FEM to analyze the BOX structure machine wall, and use high-rigidity formwork to make the mold stress evenly increase the machine wall life

B:Configure professional screw according to customer's raw material, effectively increase plasticization and wear resistance

C:Hot rolling type steel by heat treatment with excellent strength and hardness,Quench hardened with great strength.

MACHINE FUNCTIONS

| Injection Unit | ||

| Function Description | Standard | Option |

| Standard nitrided screw | ● | |

| Other made for special resins | ◎ | |

| Preumatic or hydraulic shut off nozzle | ◎ | |

| Twin injection cyliners structure | ● | |

| Carriage movement by linear transducer | ◎ | |

| Screw RPM display in controller | ● | |

| High torgue plasticising hydraulic motor | ● | |

| Digital back pressure control | ● | |

| Barrel feeding zone temperture motitor | ◎ | |

| Purge Guard | ◎ | |

| Barrel heating with insulation protection | ◎ | |

| Heating barrel supporter (above 600T) | ● | |

| Resin loading perform | ◎ | |

| Automatic lubrication system | ◎ | |

| Ceramic heater bands | ◎ | |

| Infrared heater bands | ◎ | |

| Simutaneous plasticising by Servo motor | ◎ | |

| Clamping Unit | ||

| Function Description | Standard | Option |

| Screw hole mold platen | ◎ | |

| T-slot mold platen | ● | |

| Mechanical,electric and clamping unit | ● | |

| Automatic mold height adjustment by hydraulic motor | ● | |

| All machine movements by liner transducers | ● | |

| Adjustable mold platen supporting device | ● | |

| Moving platen protectedby high rigid linear guardrod | ● | |

| Clamping zone with top cover (CE Standard) | ◎ | |

| Servo driven automatic safety door (Operator side) | ◎ | |

| Euromap 12 or 67 robot interfaces | ◎ | |

| Extended guard doors for extra UPVC fitting cyliners | ◎ | |

| Fast & Easy plugs water regulators for molds | ● | |

| Air clast device | ◎ | |

| Mold water regulators with tempature and flow control | ◎ | |

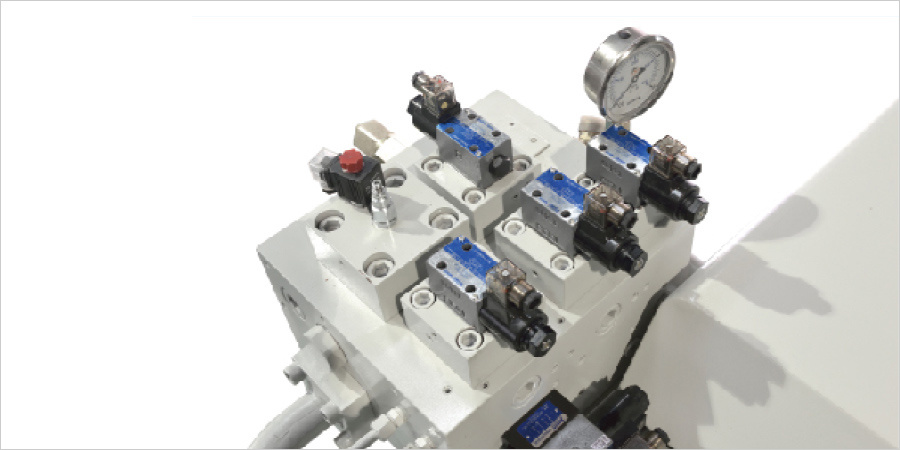

| Hydraulic Unit | ||

| Function Description | Standard | Option |

| Servo motor system | ● | |

| Variable pump | ◎ | |

| Increase pump motor capacity | ◎ | |

| Sequentisl injection system | ◎ | |

| High injection speed by accumulator | ◎ | |

| Injection servo valve | ◎ | |

| Hydraulic oil level alarm | ◎ | |

| Regeration clamping system | ● | |

| Ejector on fly | ◎ | |

| Simotaneous plasticising | ◎ | |

| Electric Unit | ||

| Function Description | Standard | Option |

| Taiwan Dizhou controller | ● | |

| European KEBA controller | ◎ | |

| Constantly monitor of machine function | ● | |

| Monitoring for production data | ● | |

| Three-color warning lamp | ● | |

| Servo motor overload protection | ● | |

| Emergency stop for both guard doors | ● | |

| Servo power system transformer | ◎ | |

| Screw cold start-up prevention | ● | |

| Safety relay monitoring | ● | |

| Heating solid relay control | ● | |

| Computer network central control system | ● | |

| Hot runner control and interface | ◎ | |

| Real time energy consumption monitor | ◎ | |

| Constantly monitor of clamping force | ● | |

| Other | ||

| Function Description | Standard | Option |

| Special color | ◎ | |

| Higher machine base | ◎ | |

| Robot | ◎ | |

| Tailor made molded product output bin | ◎ | |

Featured Products

Messages

If you are interested in our products, please leave us a message and we will contact you as soon as possible!